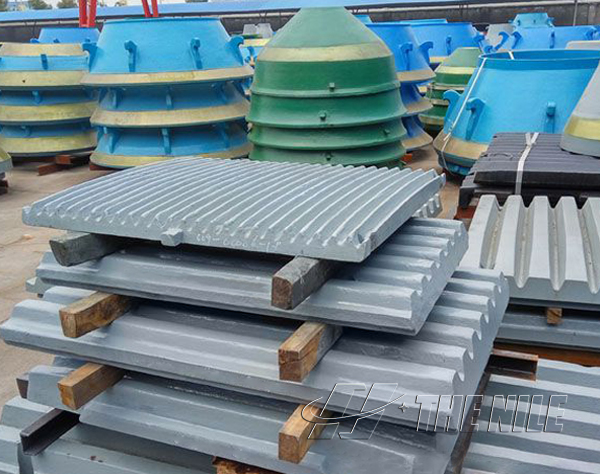

Jaw Plate Of Jaw Crusher

Applicable Crusher: Jaw Crusher

Introduction

Accessories:

The jaw crusher is composed of a working cavity composed of movable and fixed jaw plate, and the movable and fixed jaw plate bear huge crushing force and friction action of materials, so they are easy to wear out. In order to protect the jaw plate, wear-resistant lining plates are generally installed on the surfaces of moving and fixed jaw plate. This type of liner is also called a crush plate. The surface of the crush plate is usually made into tooth shape, the angle of the tooth peak of the crush plate is 90 °/ 120 °, and its size is determined by the nature and size of the crush material. When crushing the large material, the angle is larger; when the small piece of material is crush, the angle is smaller. The pitch depends on the size of the product, usually equal to the width of the outlet, and the ratio of tooth height to pitch should be 1 / 2 - 1 / 3.

When working, the wear rate of the upper and lower parts of the crush plate is different, and the lower part is worn faster than the upper part. When the crush plate is working in the jaw-type crusher, it is directly in contact with the material and bears the huge crushing force and the friction effect of the material. The service life of the crush plate is directly related to the working efficiency and production cost of the crusher, so it is particularly important to extend the service life of the crush plate of the crusher. The service life of the crush plate can be considered from the aspects of design, material selection, assembly and improvement in the process of use.

Product Advantages:

1. Quality assurance. Casting production each link has strict control system procedure, before the factory must pass the quality inspection section quality inspection, guarantees each factory product quality;

2. High value for money. The use of high manganese steel composite plate can double the production efficiency of crusher, reduce the investment cost of casting wear, reduce the stoppage loss caused by frequent replacement of spare parts, and greatly improve the return on investment.

3. Technical assurance. Can be configured according to customer personalized requirements, the product through scientific and strict smelting, casting, heat treatment process, product wear resistance greatly improved;

4. Widely used. Widely used in metallurgy, chemical industry, building materials, electricity, transportation and other industrial sectors, used in a variety of ores and rocks of coarse, medium, fine used jaw crusher.

The jaw crusher is composed of a working cavity composed of movable and fixed jaw plate, and the movable and fixed jaw plate bear huge crushing force and friction action of materials, so they are easy to wear out. In order to protect the jaw plate, wear-resistant lining plates are generally installed on the surfaces of moving and fixed jaw plate. This type of liner is also called a crush plate. The surface of the crush plate is usually made into tooth shape, the angle of the tooth peak of the crush plate is 90 °/ 120 °, and its size is determined by the nature and size of the crush material. When crushing the large material, the angle is larger; when the small piece of material is crush, the angle is smaller. The pitch depends on the size of the product, usually equal to the width of the outlet, and the ratio of tooth height to pitch should be 1 / 2 - 1 / 3.

When working, the wear rate of the upper and lower parts of the crush plate is different, and the lower part is worn faster than the upper part. When the crush plate is working in the jaw-type crusher, it is directly in contact with the material and bears the huge crushing force and the friction effect of the material. The service life of the crush plate is directly related to the working efficiency and production cost of the crusher, so it is particularly important to extend the service life of the crush plate of the crusher. The service life of the crush plate can be considered from the aspects of design, material selection, assembly and improvement in the process of use.

Product Advantages:

1. Quality assurance. Casting production each link has strict control system procedure, before the factory must pass the quality inspection section quality inspection, guarantees each factory product quality;

2. High value for money. The use of high manganese steel composite plate can double the production efficiency of crusher, reduce the investment cost of casting wear, reduce the stoppage loss caused by frequent replacement of spare parts, and greatly improve the return on investment.

3. Technical assurance. Can be configured according to customer personalized requirements, the product through scientific and strict smelting, casting, heat treatment process, product wear resistance greatly improved;

4. Widely used. Widely used in metallurgy, chemical industry, building materials, electricity, transportation and other industrial sectors, used in a variety of ores and rocks of coarse, medium, fine used jaw crusher.