The Roller Of Roll Crusher

Introduction

The double roller crusher is a new type crusher developed on the basis of digesting and absorbing the advanced technology of the same type of equipment abroad and combining with the national conditions of our country. Mainly used for coke crushing, but also for coal mines or coal preparation plant crushing raw coal and other materials similar to hardness or hardness. Compared with domestic crusher of the same size, it has the characteristics of small volume, large production capacity, reliable operation, long service life of broken tooth plate, uniform crushing particle size, convenient adjustment of discharging particle size, safety and reliability, etc.

The roller is provided with two groups, a set of active fixed rollers and a set of pressure movable rollers, which transmit power to the movable rollers through the gear bridge. Because the mechanism does not change the normal meshing relationship between the gears due to the center distance of the rollers, so that the two teeth roll always do the relative rotation synchronously.

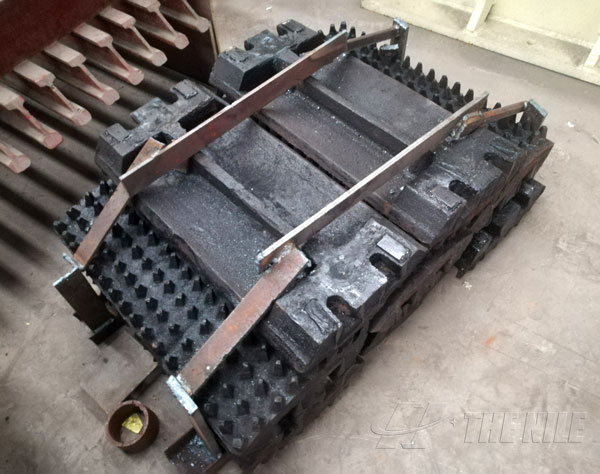

Each set of rollers is made of six crescent shaped broken tooth plates connected to the fixed frame on the roller shaft by high strength bolts. The broken tooth plates are made of high strength and high strength wear resistant alloy cast steel. The tooth surface is carburized and nitrided with penetration depth > 3mm. It has reliable wear resistance and high strength impact resistance. The continuous service life is more than 20000 hours, and the tooth plate is easy to replace after wear.

The roller is provided with two groups, a set of active fixed rollers and a set of pressure movable rollers, which transmit power to the movable rollers through the gear bridge. Because the mechanism does not change the normal meshing relationship between the gears due to the center distance of the rollers, so that the two teeth roll always do the relative rotation synchronously.

Each set of rollers is made of six crescent shaped broken tooth plates connected to the fixed frame on the roller shaft by high strength bolts. The broken tooth plates are made of high strength and high strength wear resistant alloy cast steel. The tooth surface is carburized and nitrided with penetration depth > 3mm. It has reliable wear resistance and high strength impact resistance. The continuous service life is more than 20000 hours, and the tooth plate is easy to replace after wear.