Fine sand recycling machine is a new type environment protection equipment that has been researched and developed by absorbing advanced foreign technology.

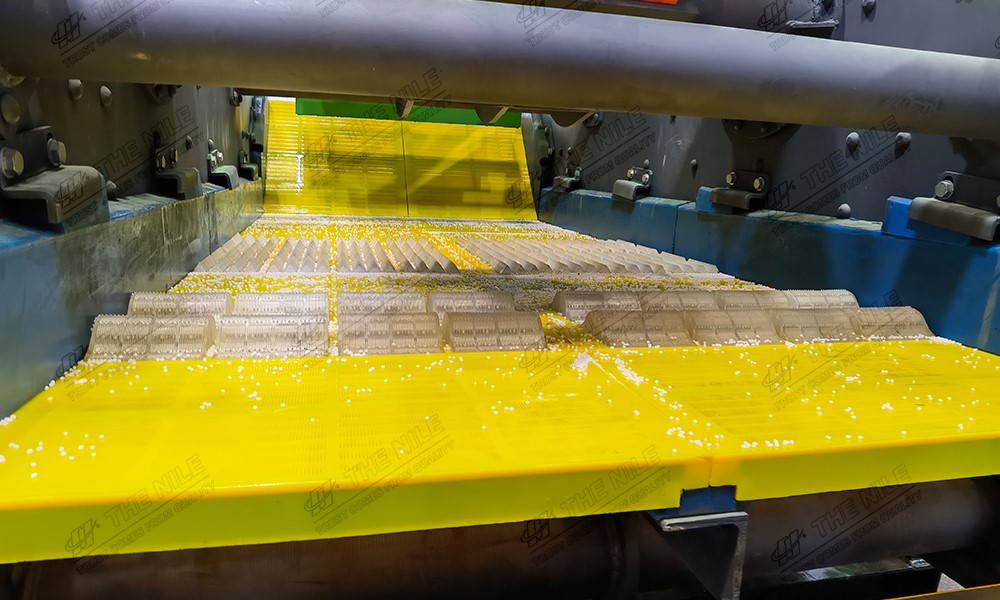

The fine sand recycling machine is mainly composed of the motor, vacuum high-pressure pump, sediment separator, TS dewatering screen, cleaning tank, and return hopper. The dewatering screen uses a polyurethane screen surface, which can absorb high-strength impact and is currently the best wear-resistant screen surface material in the world.

The sand-water mixture processed by the sand washing machine is transported to the centrifugal separator by the pump. The classified and concentrated fine sand is fed to the dehydration screen through the grit nozzle. After dehydration, the fine sand is effectively separated from the water. A small amount of fine sand and mud return to the cleaning tank through the return hopper. When the liquid level in the cleaning tank is too high, they will be discharged through the port.

The main function of the recycling machine is to clean, dehydrate and classify sand and gravel. It can well recover the large amount of fine sand lost by the sand washing machine in the traditional sand making industry. It not only improves economic benefits, but reduces the cost of tailings processing as well as the pollution and damage of the loss of fine sand to the environment.