Single cylinder rotary dryer-a multifunctional dryer meet your demand

Single cylinder rotary dryer is widely used in mineral processing, building materials, metallurgy, and chemical industry, drying a certain humidity particle of materials. The dryer has strong adaptability to materials, can dry all kinds of materials, and the operation is simple and reliable.

Rotary Dryer Applications:

1. Powder and particle: Sands, limestone, stones, clay, mineral filter cake, coal, iron sulphate, filter cakes, fly ash, gypsum etc.

2. Damp and sticky material: Coal slime, sewage sludge, bentonite, Kaolin etc.

3. Corrosive material: Distillers ‘grains, Fertilizer, animal dung, slag etc.

4. Biomass material: Sawdust, wood chips etc.

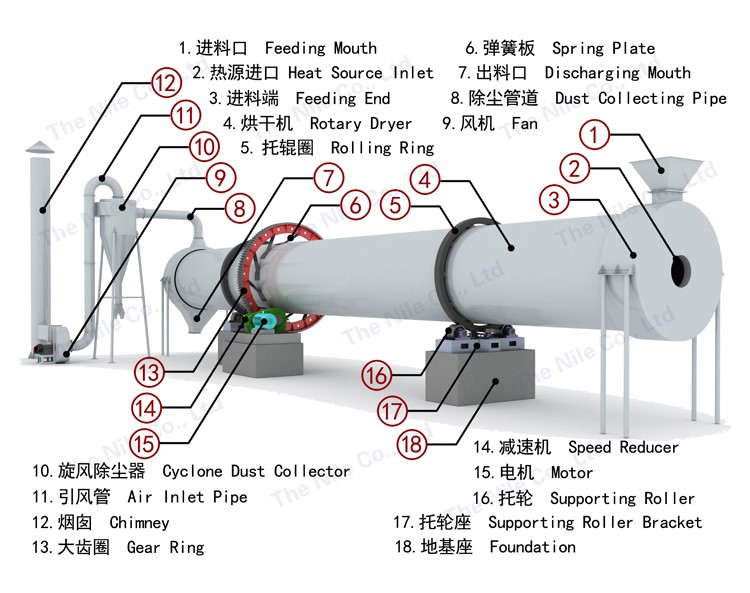

Working principle: wet material is sent to the hopper by belt conveyor or bucket elevator, and then the feeder through the hopper enters the feeding port through the feeding pipe. The inclination of the feeding pipe should be greater than the natural inclination of the material, so that the material can flow into the dryer smoothly. The dryer cylinder is a rotating cylinder slightly inclined to a horizontal line.The material is feeded from the higher end, the heat carrier enters from the lower end and is in contact with the material in a countercurrent, and also the heat carrier and the material flow downstream into the cylinder body. A material lifting plate is installed on the inner wall of the cylinder body, and its function is to lift up and scatter the material, increase the contact surface between the material and the air flow, increase the drying speed and promote the material advance.

Nile Single cylinder rotary dryer Advance:

Nile Single cylinder rotary dryer Advance:

1.International standard with ISO, CE certificate.

2.Simple system, safe and easy operation.

3.Flexibility in fuels used (NG, Oil, Coal ect.).

4.Year of experience with all types of dryers.

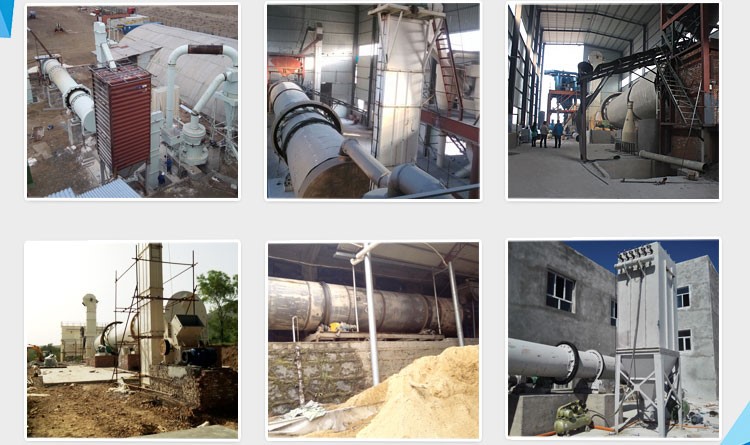

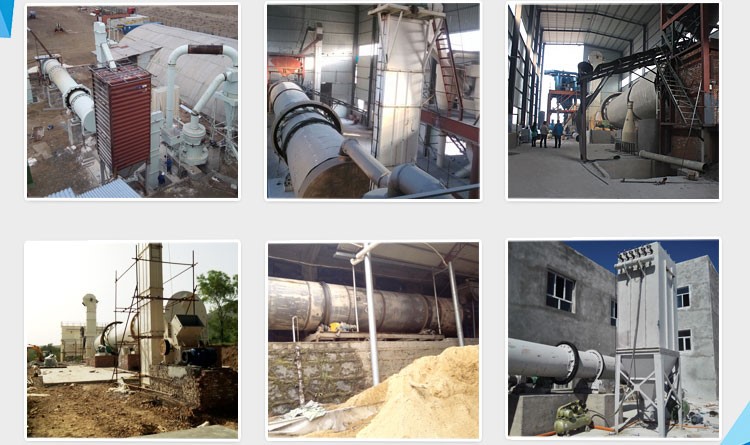

5.Capable of installation anywhere in world.

6.In house engineering for custom fit applications.

The Nile CO., LTD could provide you professional installation guidance and after-sale service about single cylinder double cylinder and three cylinder rotary dryer, look forward to long term cooperation.

Rotary Dryer Applications:

1. Powder and particle: Sands, limestone, stones, clay, mineral filter cake, coal, iron sulphate, filter cakes, fly ash, gypsum etc.

2. Damp and sticky material: Coal slime, sewage sludge, bentonite, Kaolin etc.

3. Corrosive material: Distillers ‘grains, Fertilizer, animal dung, slag etc.

4. Biomass material: Sawdust, wood chips etc.

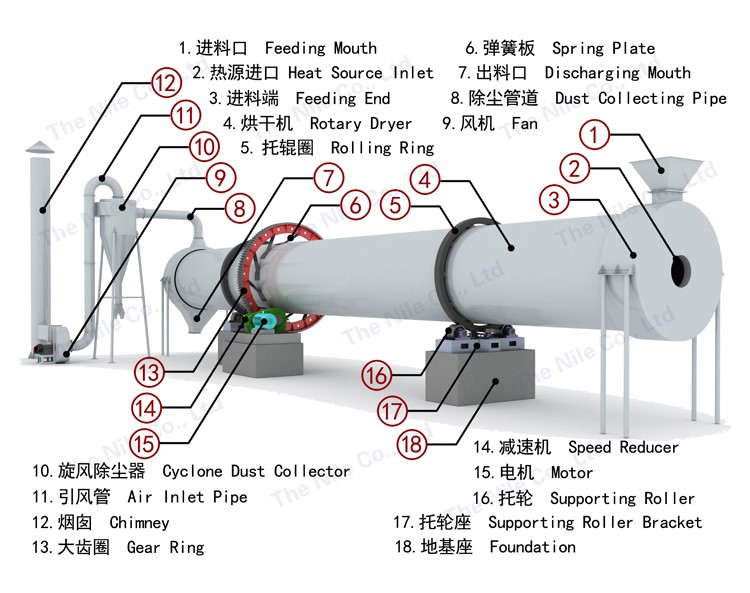

Working principle: wet material is sent to the hopper by belt conveyor or bucket elevator, and then the feeder through the hopper enters the feeding port through the feeding pipe. The inclination of the feeding pipe should be greater than the natural inclination of the material, so that the material can flow into the dryer smoothly. The dryer cylinder is a rotating cylinder slightly inclined to a horizontal line.The material is feeded from the higher end, the heat carrier enters from the lower end and is in contact with the material in a countercurrent, and also the heat carrier and the material flow downstream into the cylinder body. A material lifting plate is installed on the inner wall of the cylinder body, and its function is to lift up and scatter the material, increase the contact surface between the material and the air flow, increase the drying speed and promote the material advance.

1.International standard with ISO, CE certificate.

2.Simple system, safe and easy operation.

3.Flexibility in fuels used (NG, Oil, Coal ect.).

4.Year of experience with all types of dryers.

5.Capable of installation anywhere in world.

6.In house engineering for custom fit applications.

The Nile CO., LTD could provide you professional installation guidance and after-sale service about single cylinder double cylinder and three cylinder rotary dryer, look forward to long term cooperation.