Wet pan mill— the first choice for medium and small beneficiation

Wet pan mill is also called wet grinding machine and gold grinding mill, it’s a modernized grinding machine, commonly used in the small and medium size concentrate factory. It is widely applied to the grinding and benefication of all kinds of metal minerals, non-metal minerals, rare metal and other materials. Such as gold, silver, lead, zinc, molybdenum, iron, copper, antimony, tungsten, tin and so on.

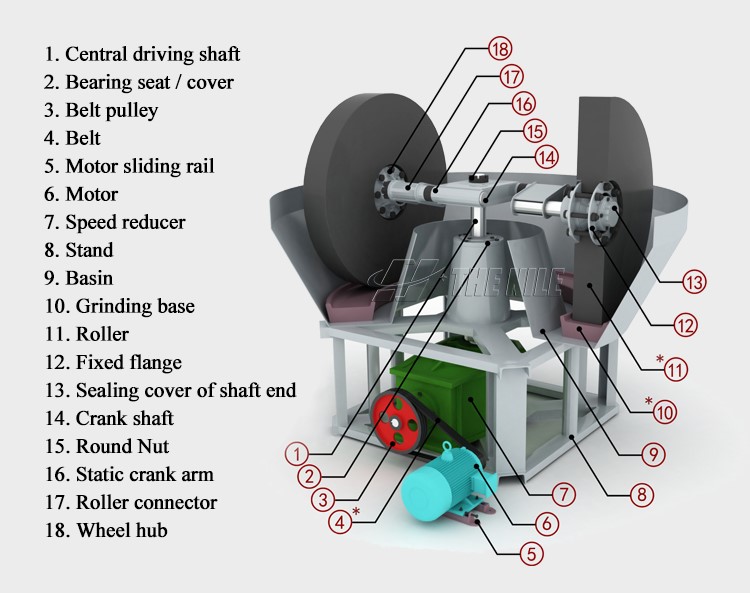

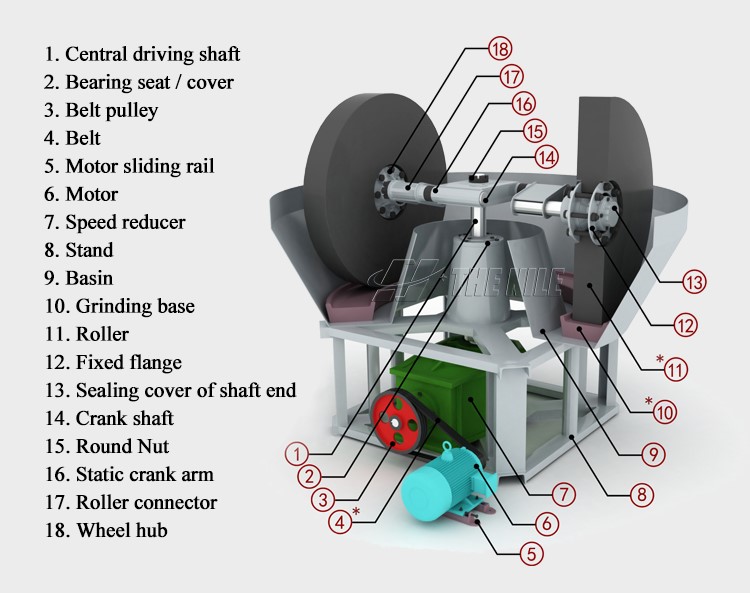

Wet pan mill grinds ores by wheel driving force. Firstly, the power is transferred from the motor to the reducer, then to the horizontal shaft, and finally to the grinding wheel; the wheels then rotate anticlockwise.The wheels can revolve around the vertical shaft of the pan mill, and at the same time, it can revolve on its own axis, while the grinding base will remain still. The ores are pressed, rubbed and grinded repeatedly.

Wet pan mill grinds ores by wheel driving force. Firstly, the power is transferred from the motor to the reducer, then to the horizontal shaft, and finally to the grinding wheel; the wheels then rotate anticlockwise.The wheels can revolve around the vertical shaft of the pan mill, and at the same time, it can revolve on its own axis, while the grinding base will remain still. The ores are pressed, rubbed and grinded repeatedly.

Main features:

Main features:

1. Professionally-designed, thus its technical data is reasonable.

2.Short grinding and mixing cycle, high efficiency.

3.Low noise and low consumption. The materials can be grinded and mixed uniformly.

4.Compact structure, easy to operate and maintenance.

The Nile’s wet pan mill introduction of advanced core technology, wear-resisting improve more than 130%, choose The Nile’s wet pan mill, make more money for yourself.

The Nile’s wet pan mill introduction of advanced core technology, wear-resisting improve more than 130%, choose The Nile’s wet pan mill, make more money for yourself.

1. Professionally-designed, thus its technical data is reasonable.

2.Short grinding and mixing cycle, high efficiency.

3.Low noise and low consumption. The materials can be grinded and mixed uniformly.

4.Compact structure, easy to operate and maintenance.