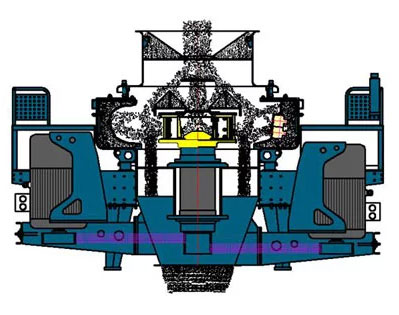

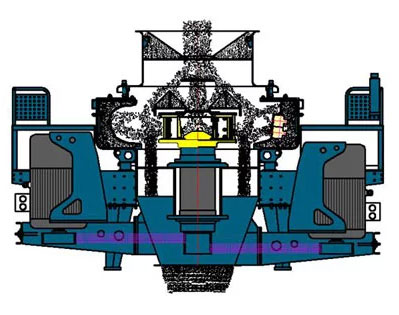

Brief Introduction Of VSI Sand Making Machine

VSI sand making machine is widely used for fine crusher and coarse grinding of metal and non metal ores, cement, refractory material, grinding material, glass raw material, building aggregates, artificial sand and all kinds of metallurgical slags. It is especially suitable for medium hardness materials, high hardness materials and corrosion resistance materials, such as carborundum, emery, magnesia etc.

Sand Making Machine Working Principle

Sand Making Machine Working Principle

1. Central feeding: Raw materials fall down into the feeding hopper of the VSI sand making machine, then enters the impeller through central entrance inlet, thus the material being accelerated by the high-speed impeller and being thrown out at the speed of 60-75m/s. It is crushed when hitting the impact plate, and the end products comes out from the discharging outlet.

2. Ring feeding: Raw materials fall down into the feeding hopper, and the materials are divided into two parts by a special plate. Some materials enter the sand making machine’s impeller through the center of the plate and the other part of materials falls down from outside of the plate. The materials thrown out earlier crush the materials down from outside, thus the materials crushed and re-crushed.

The Nile’s VSI Sand Making Machine Features:

The Nile’s VSI Sand Making Machine Features:

1. Unique structure and stable operation.

2. Low energy consumption, large capacity and crushing ratio.

3. Perfect cubic product size and high bulk density.

4. Less spare parts. Spare parts are made of special hard material, which make them of long service life and easy to change.

1. Central feeding: Raw materials fall down into the feeding hopper of the VSI sand making machine, then enters the impeller through central entrance inlet, thus the material being accelerated by the high-speed impeller and being thrown out at the speed of 60-75m/s. It is crushed when hitting the impact plate, and the end products comes out from the discharging outlet.

2. Ring feeding: Raw materials fall down into the feeding hopper, and the materials are divided into two parts by a special plate. Some materials enter the sand making machine’s impeller through the center of the plate and the other part of materials falls down from outside of the plate. The materials thrown out earlier crush the materials down from outside, thus the materials crushed and re-crushed.

1. Unique structure and stable operation.

2. Low energy consumption, large capacity and crushing ratio.

3. Perfect cubic product size and high bulk density.

4. Less spare parts. Spare parts are made of special hard material, which make them of long service life and easy to change.