Which Type of Crusher Should be Used for Granite Crushing

Granite is a kind of industrial raw material with beautiful appearance and high hardness with the special advantages of wear resistance, corrosion resistance and oxidation resistance. It is an ideal raw material for construction, sculpture, highway, building materials and other fields. In order to achieve the application effect, it is necessary to crush and process granite. So which type of crusher should be used to crush granite? This is a problem that many users are very concerned about. As a professional crusher manufacturer, Nile Machinery has conducted in-depth research on the characteristics of granite and recommends several granite crushing equipment with very good effects.

1. Jaw crusher

1. Jaw crusher

Jaw crusher is a kind of crushing equipment commonly used in granite processing plant. It usually includes two types: coarse jaw crusher and fine jaw crusher. Compared with the same type of equipment on the market, the jaw crusher of Nile Machinery has the following advantages.

(1) High output: the structure design of crushing chamber is reasonable, and it can contain more granite materials, which makes the processing capacity of the equipment per unit time very large, and the output is also higher than 5 times of ordinary jaw crushers.

(2) Low cost: Granite jaw crusher adopts energy-saving motor device, which reduces power consumption by more than 30% and improve the energy saving effect of the system by more than 2 times under the condition of constant output. Moreover, the failure rate of the equipment is low and the maintenance cost is low.

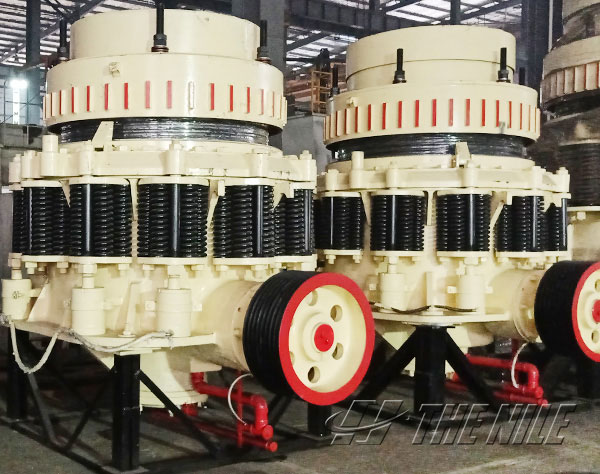

(3) Low price: on the premise of ensuring the quality, the manufacturing cost of Nile machinery has been reduced. Therefore, the price of jaw crusher is much lower than the market price. 2. Single cylinder cone crusher

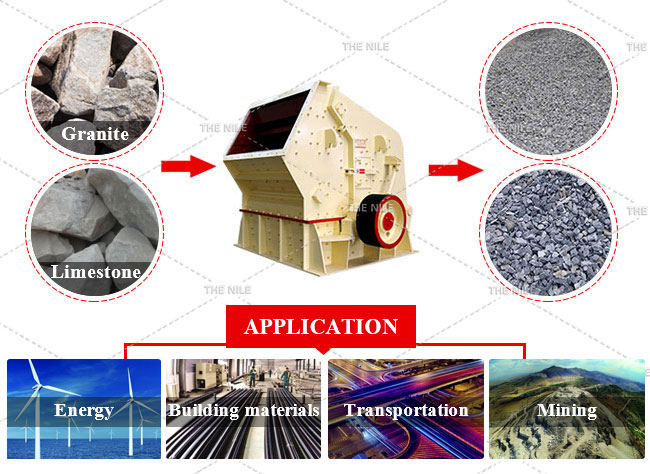

Single cylinder cone crusher adopts the laminated crushing principle and has a variety of standard crushing cavity types, which has a better crushing effect on granite and makes the finished granite has uniform grain size and better grain shape. The structure of single cylinder cone crusher is simple and can be operated by one button. The integrated design of the hydraulic station and the lubrication station can not only ensure the power required for the normal operation of the equipment, but also save the installation space. 3. Impact Crusher

Impact crusher is used for the fine crushing of granite materials.The material is crushed by friction, collision, and squeezing with the impact board, making it more crushing and less grinding. After being processed by the impact crusher, the granite stone has less needle flakes and less powder. 4. VSI sand making machine

The VSI sand making machine is used to re-process the finely crushed granite. It use PLC control technology with simple operation, low energy consumption, deep cavity impeller design and fine rotor operation, which makes the processed granite sand product have uniform particle size and good grain shape. Moreover, the ingenious structure design can make the stone material form a protective bottom layer in the crushing cavity, which has no wear to the machine body and the equipment is more durable. 5. Fine crusher

Fine crusher can not only finely crush granite, but also make granite into sand. The granite processed by the fine crusher has a uniform particle size and can reach the standard of construction sand.

Since the properties of granite in different regions are different, there are also certain differences in the selection of crusher types. Nile Machinery will configure suitable crusher types for users according to their production requirements and the characteristics of granite to achieve the best crushing effect. Interested users are welcome to contact 008615137168510 directly for consultation.

Jaw crusher is a kind of crushing equipment commonly used in granite processing plant. It usually includes two types: coarse jaw crusher and fine jaw crusher. Compared with the same type of equipment on the market, the jaw crusher of Nile Machinery has the following advantages.

(1) High output: the structure design of crushing chamber is reasonable, and it can contain more granite materials, which makes the processing capacity of the equipment per unit time very large, and the output is also higher than 5 times of ordinary jaw crushers.

(2) Low cost: Granite jaw crusher adopts energy-saving motor device, which reduces power consumption by more than 30% and improve the energy saving effect of the system by more than 2 times under the condition of constant output. Moreover, the failure rate of the equipment is low and the maintenance cost is low.

(3) Low price: on the premise of ensuring the quality, the manufacturing cost of Nile machinery has been reduced. Therefore, the price of jaw crusher is much lower than the market price. 2. Single cylinder cone crusher

Single cylinder cone crusher adopts the laminated crushing principle and has a variety of standard crushing cavity types, which has a better crushing effect on granite and makes the finished granite has uniform grain size and better grain shape. The structure of single cylinder cone crusher is simple and can be operated by one button. The integrated design of the hydraulic station and the lubrication station can not only ensure the power required for the normal operation of the equipment, but also save the installation space. 3. Impact Crusher

Impact crusher is used for the fine crushing of granite materials.The material is crushed by friction, collision, and squeezing with the impact board, making it more crushing and less grinding. After being processed by the impact crusher, the granite stone has less needle flakes and less powder. 4. VSI sand making machine

The VSI sand making machine is used to re-process the finely crushed granite. It use PLC control technology with simple operation, low energy consumption, deep cavity impeller design and fine rotor operation, which makes the processed granite sand product have uniform particle size and good grain shape. Moreover, the ingenious structure design can make the stone material form a protective bottom layer in the crushing cavity, which has no wear to the machine body and the equipment is more durable. 5. Fine crusher

Fine crusher can not only finely crush granite, but also make granite into sand. The granite processed by the fine crusher has a uniform particle size and can reach the standard of construction sand.

Since the properties of granite in different regions are different, there are also certain differences in the selection of crusher types. Nile Machinery will configure suitable crusher types for users according to their production requirements and the characteristics of granite to achieve the best crushing effect. Interested users are welcome to contact 008615137168510 directly for consultation.